APPLICATIONS

Surface, Wavefront, and Alignment Testing

CGH metrology unlocks a host of testing applications that improve efficiency and precision in optics fabrication and production.

Optical Surface Testing

Complex surface metrology enabled by CGHs

Significant advances in optical manufacturing techniques have made it possible to produce complex optical surfaces to extreme precision. Often, metrology is the limiting factor in fabricating complex optical surfaces, as methods for qualification and feedback are not precise, flexible, or capable enough. A CGH overcomes many of these surface testing challenges to make optical surface qualification feasible for most complex surfaces while maintaining precision, resolution, speed and other benefits.

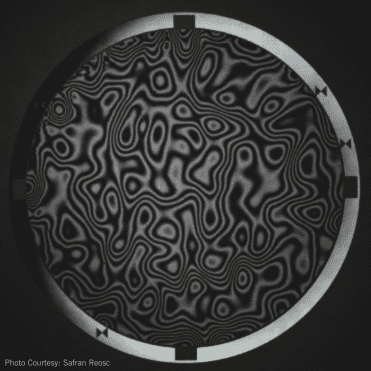

A CGH converts an interferometer regular wavefront (collimated or spherical) into a custom-designed wavefront that matches the unique shape of the surface to be tested. The result is an interferometric null test when the test optic is well aligned to the CGH.

Another way to describe this is to consider how the interferometer light rays behave in a test. A CGH is designed to bend rays in a prescribed way across the aperture, such that all rays reach the test optic at normal incidence. The result is that all rays auto-reflect from the test surface and return through the CGH to the interferometer on the same path that they exited – a null test!

A CGH null test can be designed for convex, concave, asphere, conics, off-axis sections, and even freeform surfaces. Limitations exist, but the vast majority of optical surfaces can be tested using a CGH.

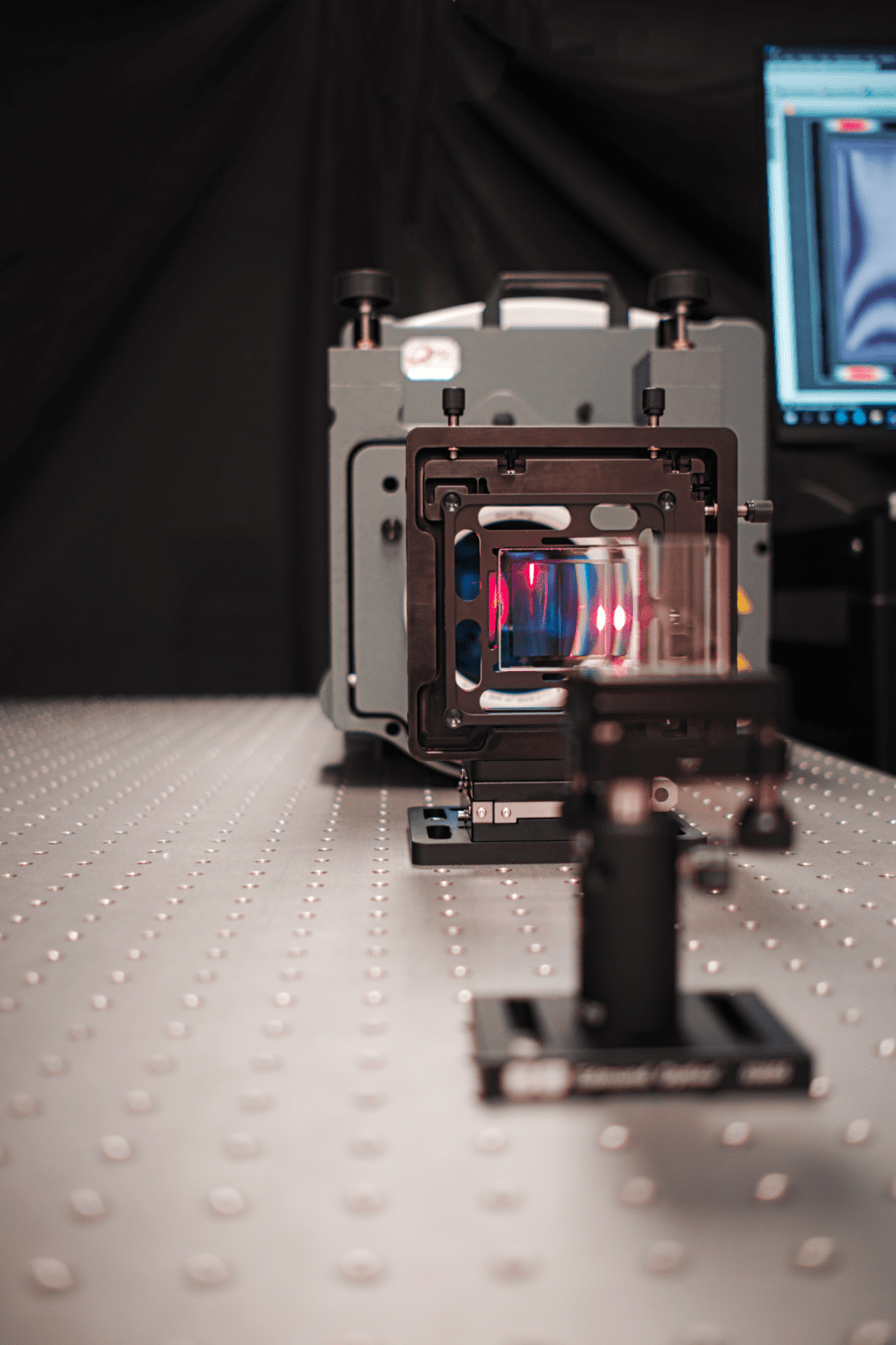

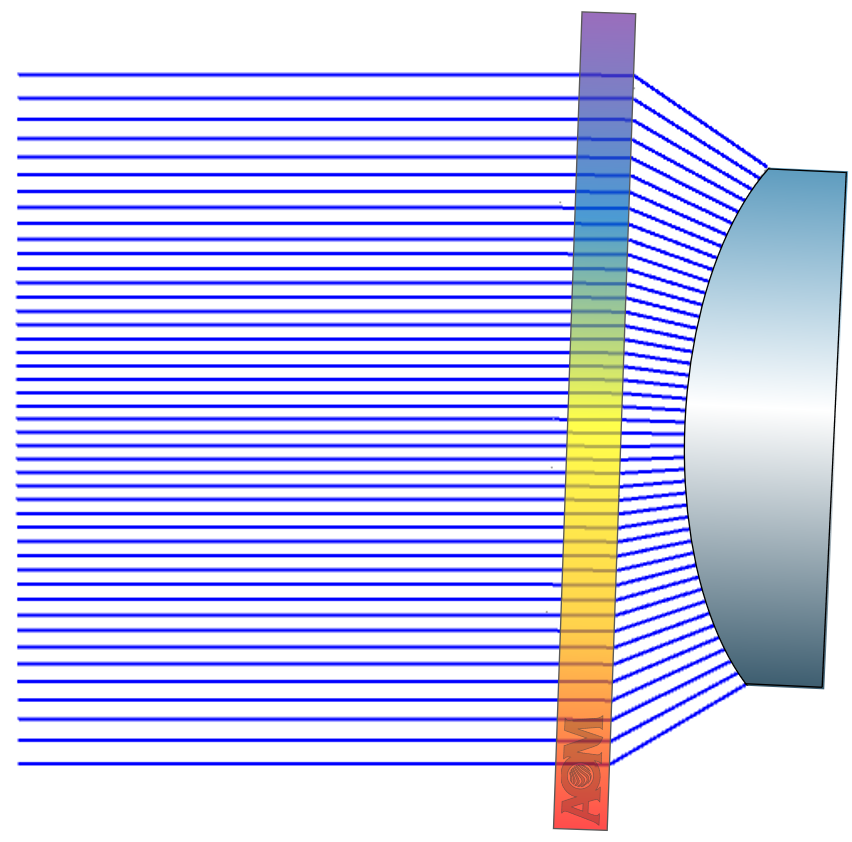

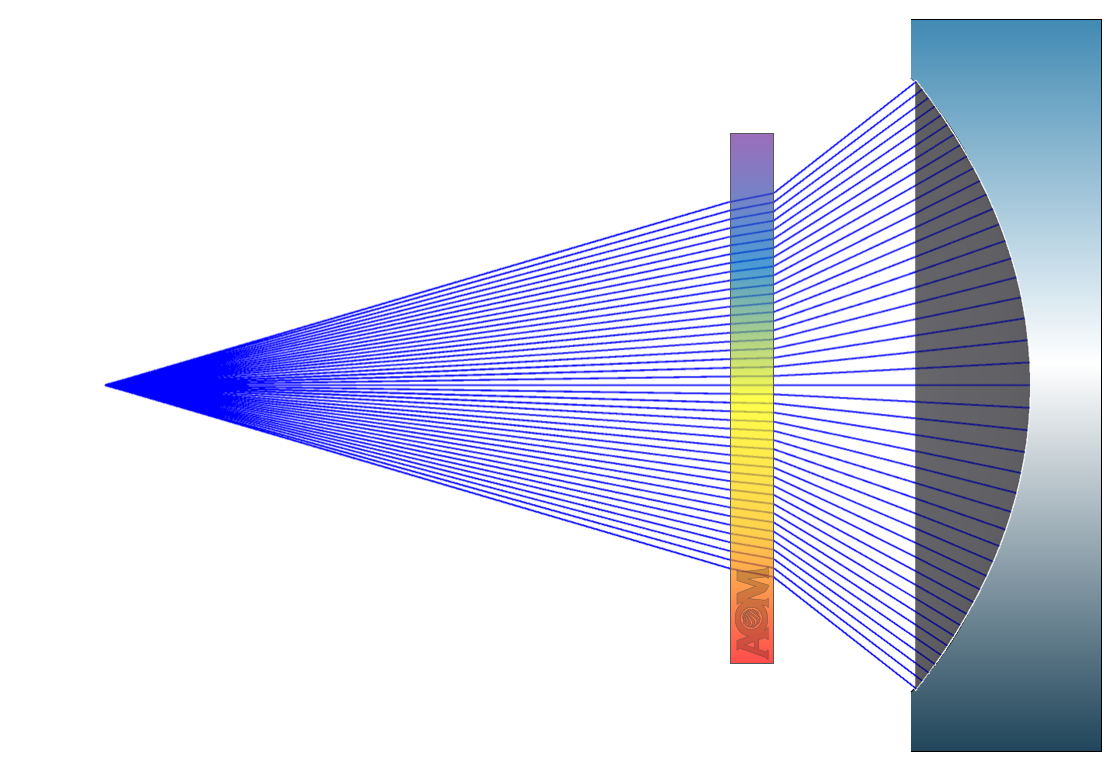

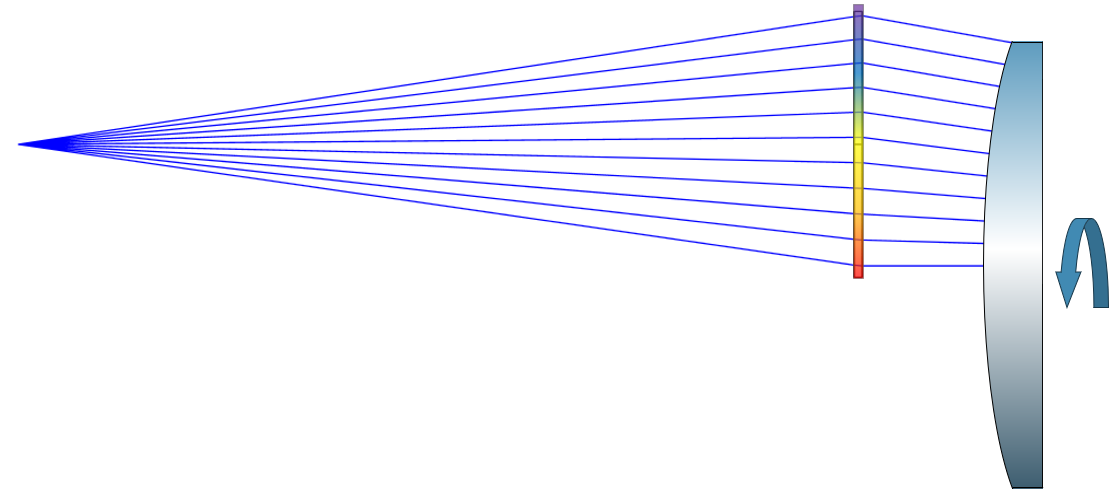

Convex Even Asphere CGH Null Test

The CGH converts a collimated wavefront to a converging wavefront with varying slope to match the convex aspheric shape.

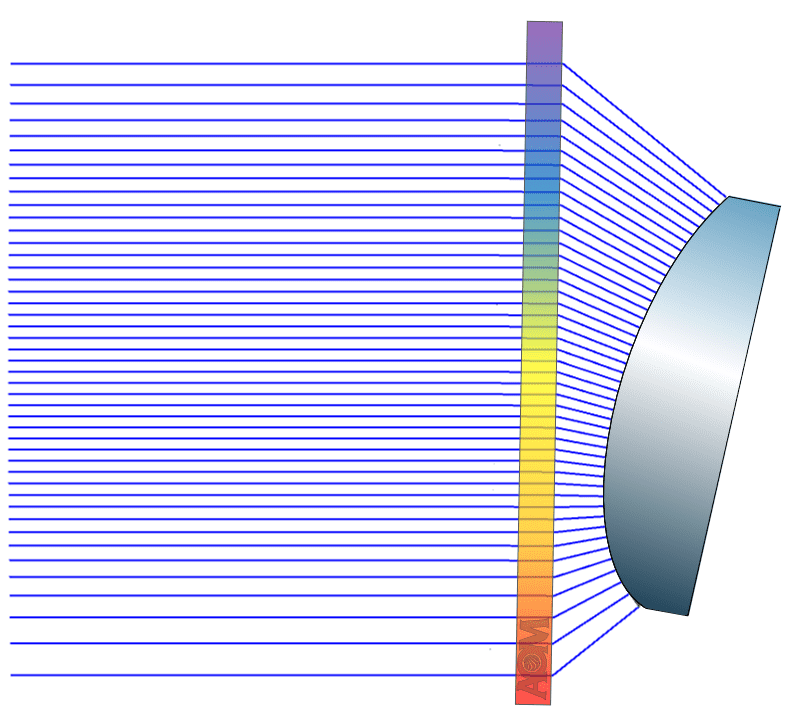

Concave Conic CGH Null Test

The CGH converts a diverging spherical wavefront to an aspheric wavefront to match the concave aspheric shape.

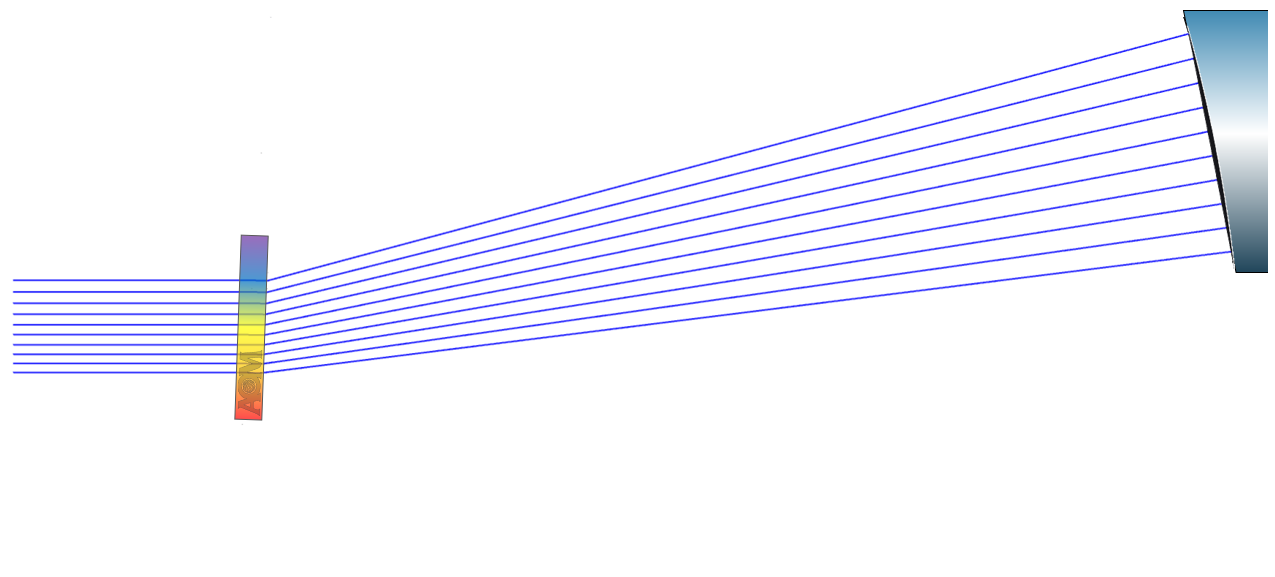

Off-Axis Conic CGH Null Test

The CGH converts a collimated wavefront to a conic wavefront to match the convex aspheric shape.

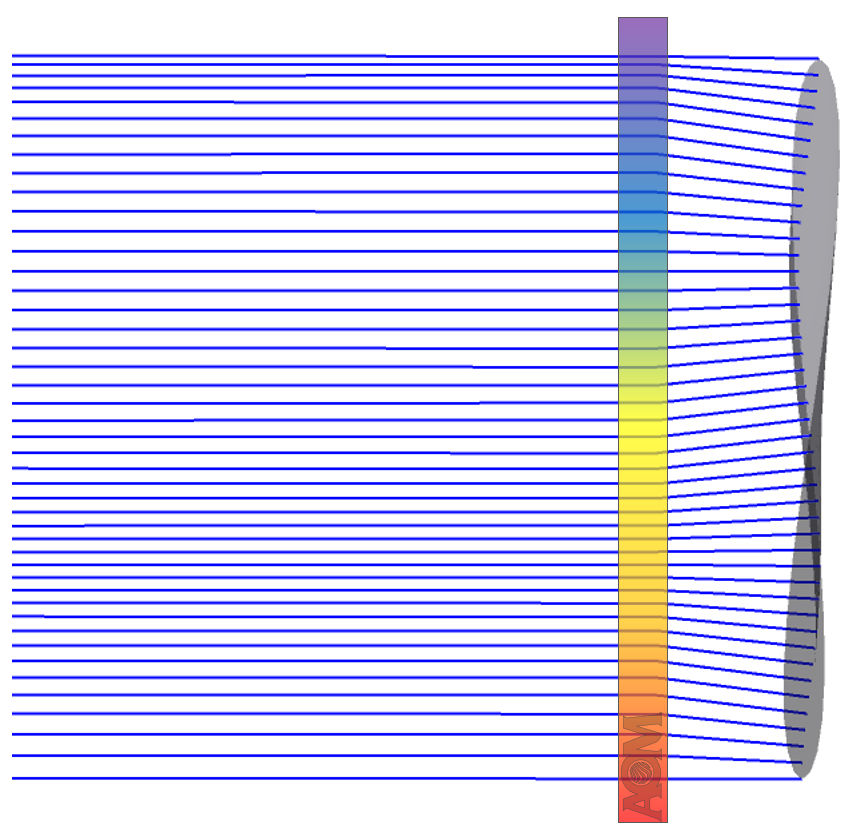

Off-Axis Parabola (OAP) CGH Null Test

The CGH converts a collimated wavefront to a diverging wavefront and off-axis angle varying slope to match the off-axis parabola.

Freeform CGH Null Test

The CGH converts a collimated wavefront to a freeform shape to match the freeform optic design.

Off-Axis CGH Section for Stitching Large Convex Surface

A CGH designed for an off-axis portion of a large rotationally symmetric asphere, the surface can be rotated and subapertures measured and stitched to qualify the complete surface.

System Wavefront & Alignment Testing

Unique system testing enabling subsystem alignment and field testing.

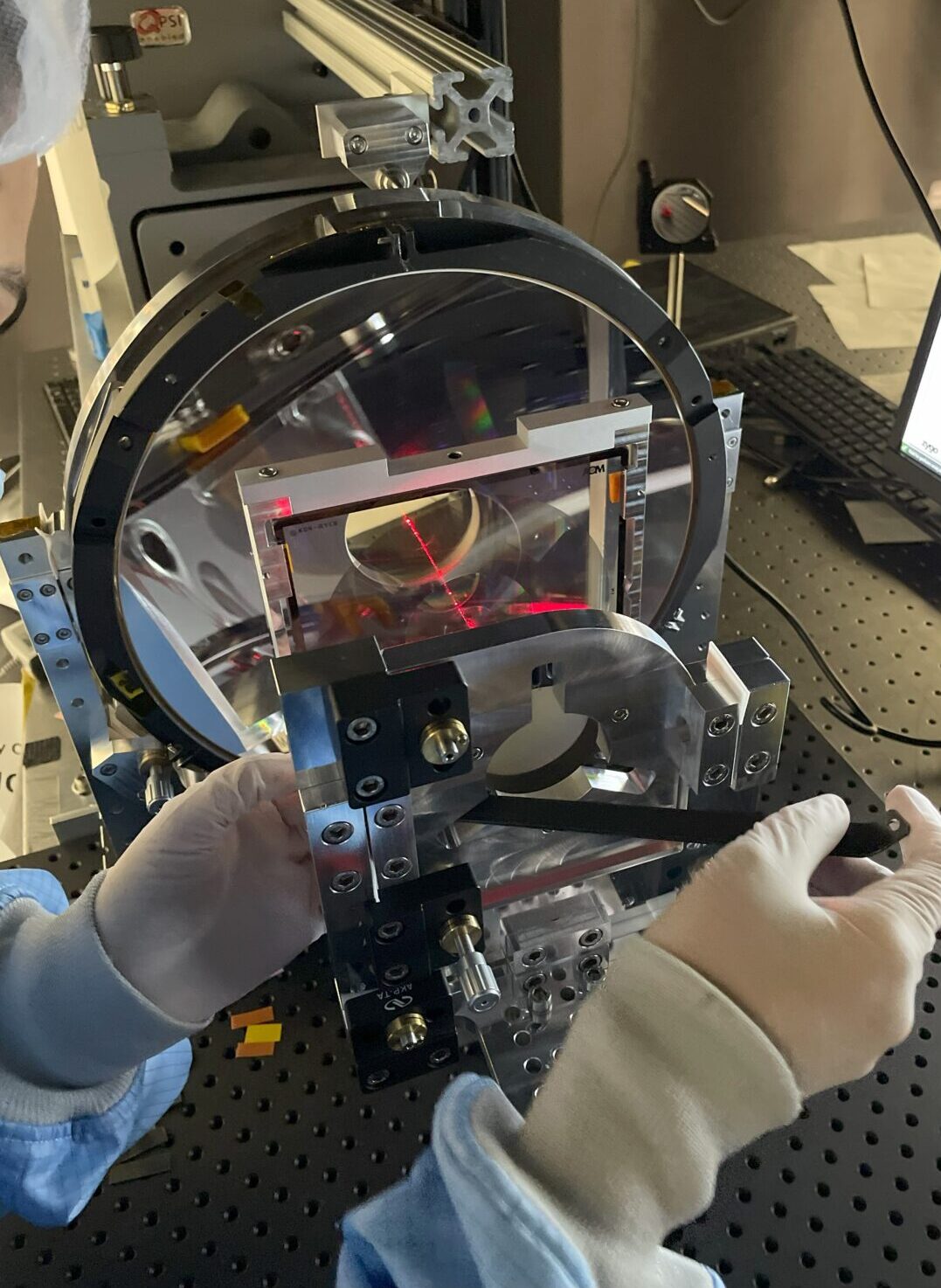

Optical subsystems perform as designed in the complete system they are designed for but can be difficult to test independently. Testing a subsystem on its own can be beneficial to ensure proper performance prior to assembly in the final system, enabling active alignment during production, or even incoming inspection from a vendor or final QC for shipment to a customer.

A CGH can enable an interferometric test of a subsystem that is not well-corrected on its own. By simulating the expected uncorrected wavefront that the subsystem is designed for, a CGH becomes a precision surrogate and reference to test the subsystem performance.

For corrected systems or subsystems, field point testing is often a critical parameter to test. However, the traditional methods of this test can be tedious, time-consuming, and prone to error. With a CGH, test multiple field points with a static interferometer setup for improved precision and ease of use.

Even surface-to-surface metrology is possible – with multiple patterns on a CGH, target multiple surfaces simultaneously to quantify surface-to-surface characteristics of a lens element.

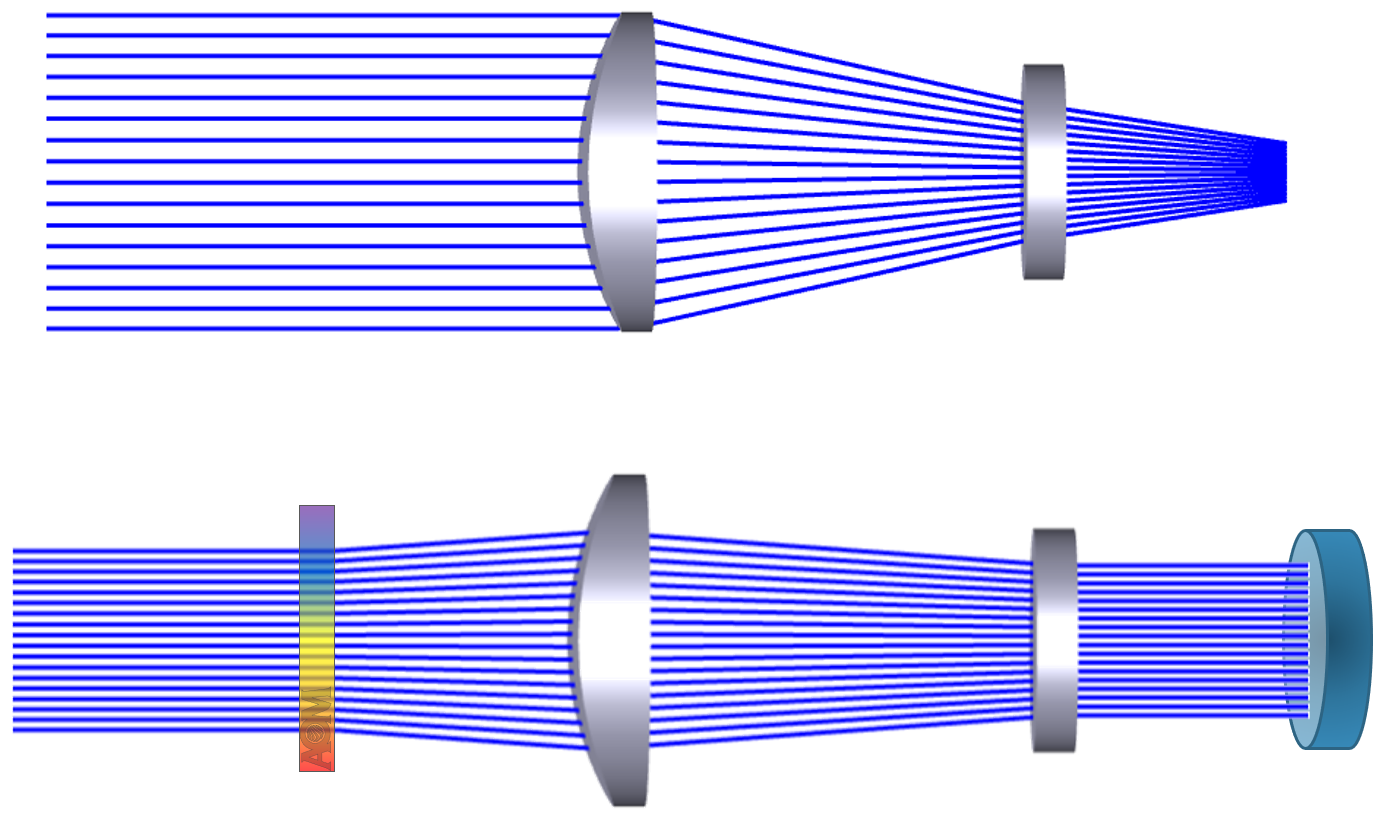

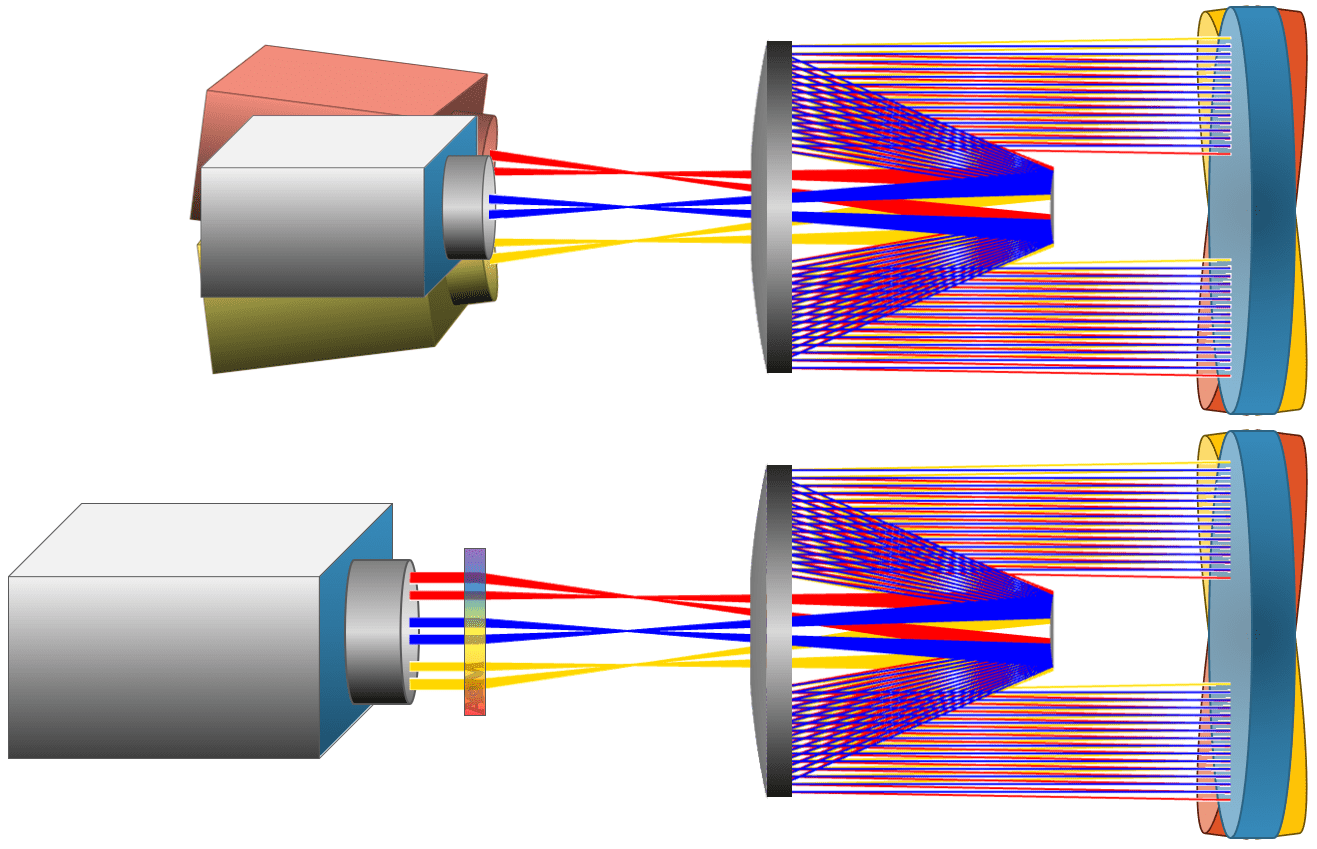

Optical Subsystem Test

Top: A two-element subsystem with infinite conjugate and uncorrected output by design.

Bottom: A CGH adjusts the input wavefront to enable a collimated output wavefront, enabling infinite conjugate testing of the subsystem.

Field Point Test

Top: A primary/secondary telescope subsystem is tested at different field points with the traditional method of moving the interferometer and tilting the return flat.

Bottom: A CGH-enabled field test provides multiple field points in the interferometer aperture simultaneously, only tilt of the return flat is required to test multiple field points.

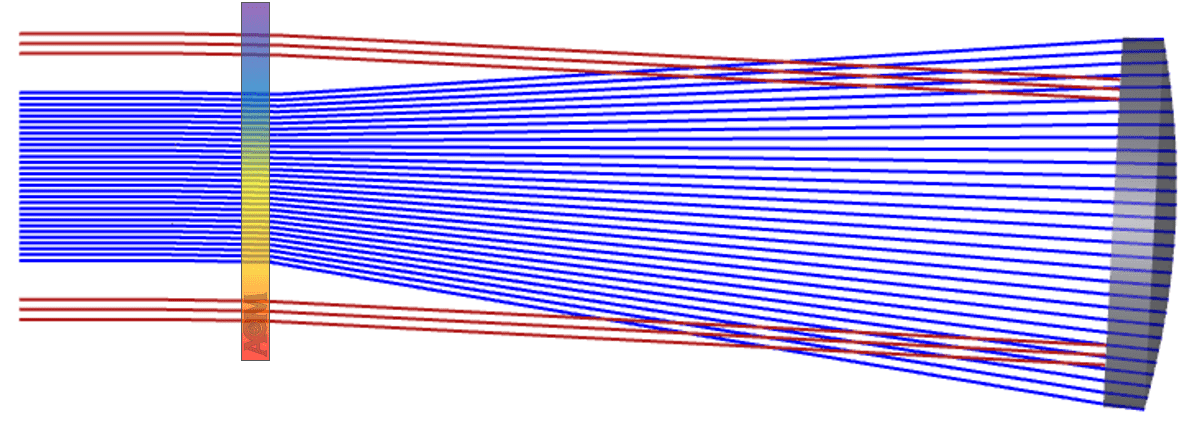

Surface-to-Surface Test

A CGH is designed with multiple patterns that target a lens element’s front and back surfaces. The returns are compared simultaneously in the interferogram and can provide a lens element’s critical wedge and centration metrology.